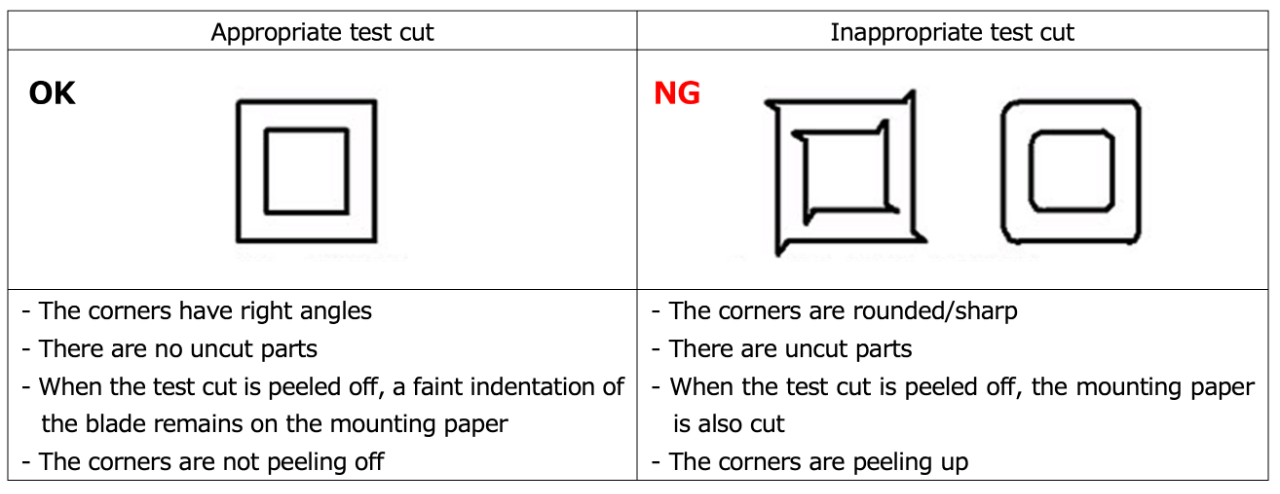

- Follow the steps below and make sure to confirm that the test cut result is appropriate before cutting the data.

How to confirm the test cut results

If the test result of the test cut is inappropriate, check the following corrective actions.

| Symptoms | Symptoms | Checkpoints |

|---|---|---|

| The corners are rounded/ sharp | The blade offset value is inappropriate | Check “Corrective action 1” |

| There are uncut parts | The cutter holder is loose, or the cutting speed is too fast, causing the blade tip or sheet to lift up | Check “Corrective action 2” |

| The blade tip protrusion amount is too small | Check “Corrective action 3” | |

| The cutting pressure is too low | Check “Corrective action 4” | |

| The mounting paper is cut | The cutting pressure is too high | Check “Corrective action 4” |

| The blade tip protrusion amount is too large | Check “Corrective action 3” | |

| The corners are peeling up | The blade tip protrusion amount is too large | Check “Corrective action 3” |

| The cutting pressure is too high | Check “Corrective action 4” | |

| The [ADJ-PRS OFS] value is too large. | Check “Corrective action 5” |

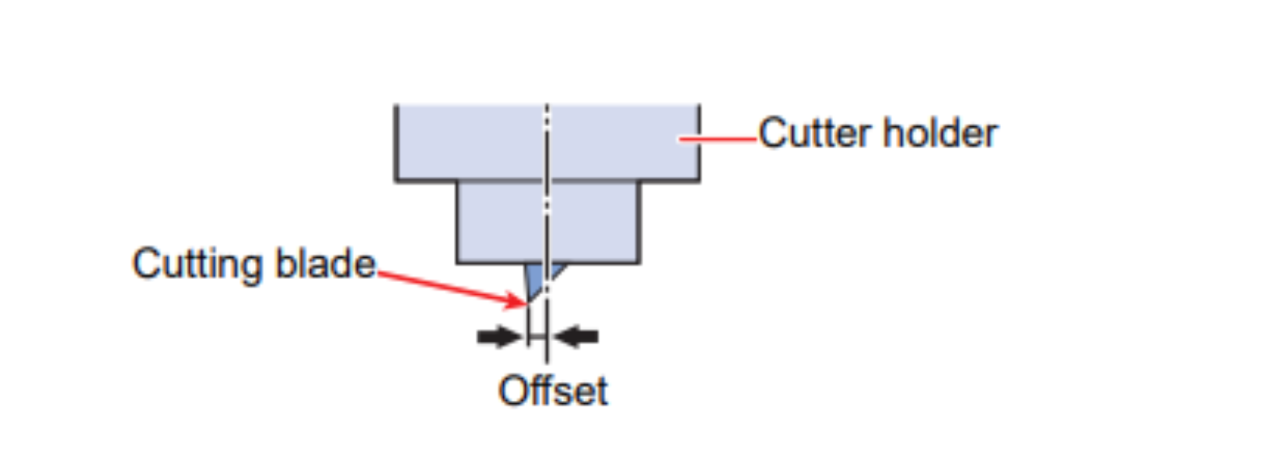

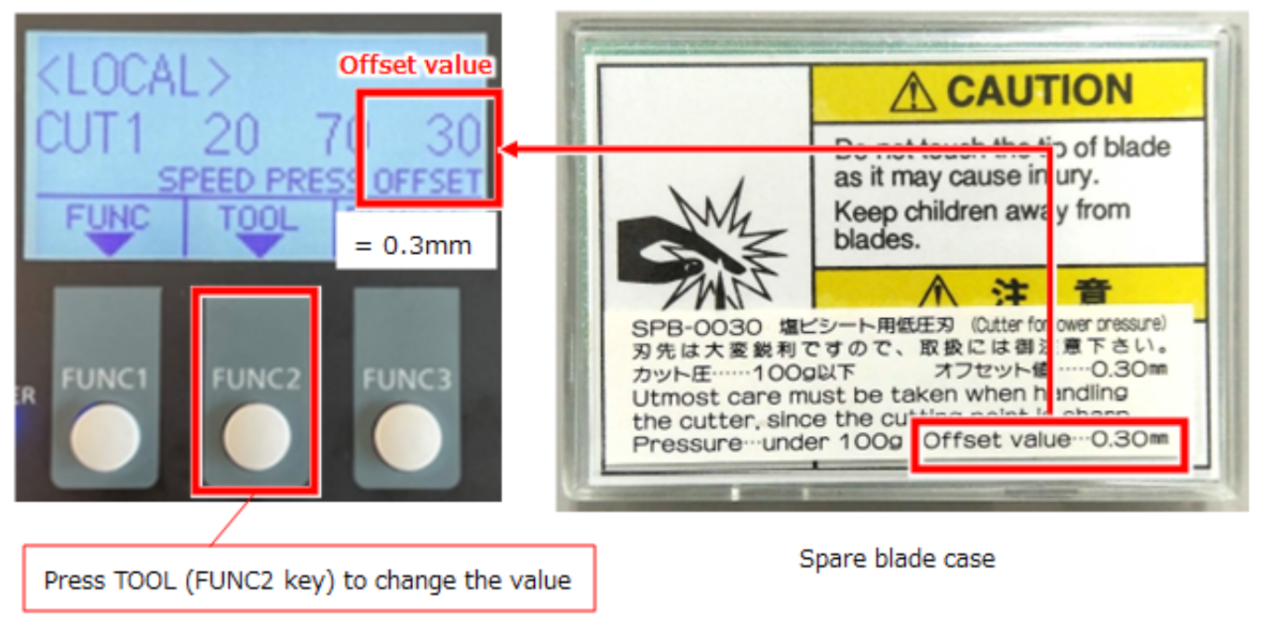

Corrective action 1 The term "offset value (OFFSET)" refers to the distance from the center of the cutter holder to the blade tip. If the offset value is not appropriate, the corners of the test cut may become rounded or sharp. The offset value is determined for each type of blade, so please set it to the appropriate value. The offset value is listed on the spare blade case. Setting range of offset value: 0 (0.00mm) to 250 (2.50mm)

Example) Offset value for the included blade: 30 (=0.30mm)

(Product name: Swivel Blade for PVC with low-pressure, Item coder: SPB-0030)

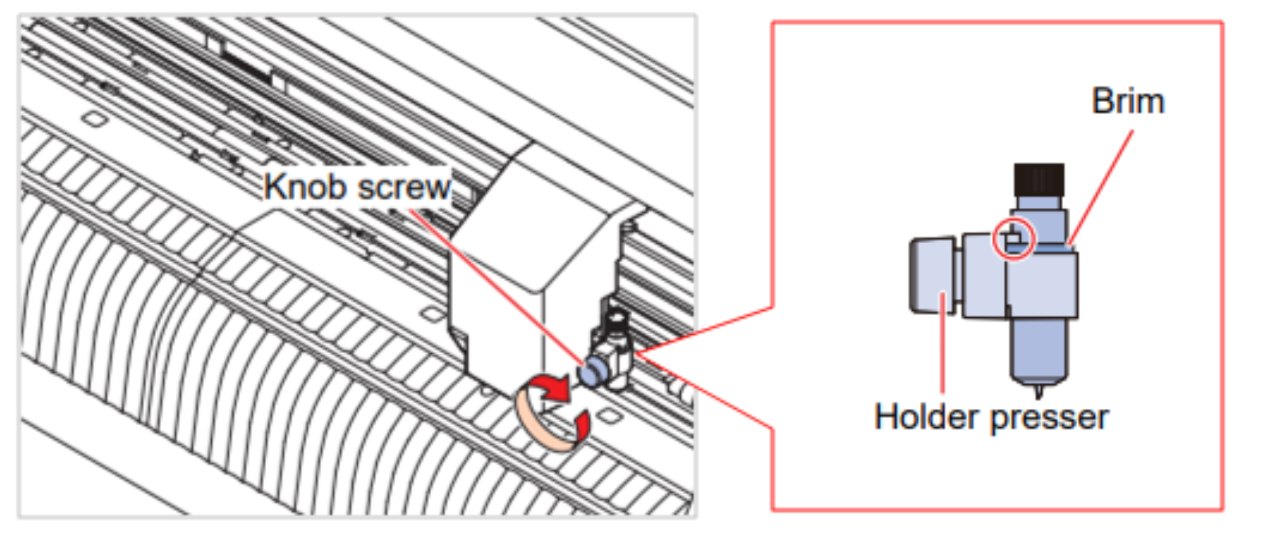

The recommended speed (SPEED), pressure (PRESS), and offset (OFFSET) settings for each type of blade can be found in the video "Mimaki CG Series Introduction of 6 blade types". Corrective action 2 If the cutter holder is loose or the cutting speed is too fast, the blade tip or sheet may lift up and not cut properly. (1) Secure the cutter holder Turn the knob clockwise and firmly fix it in place.

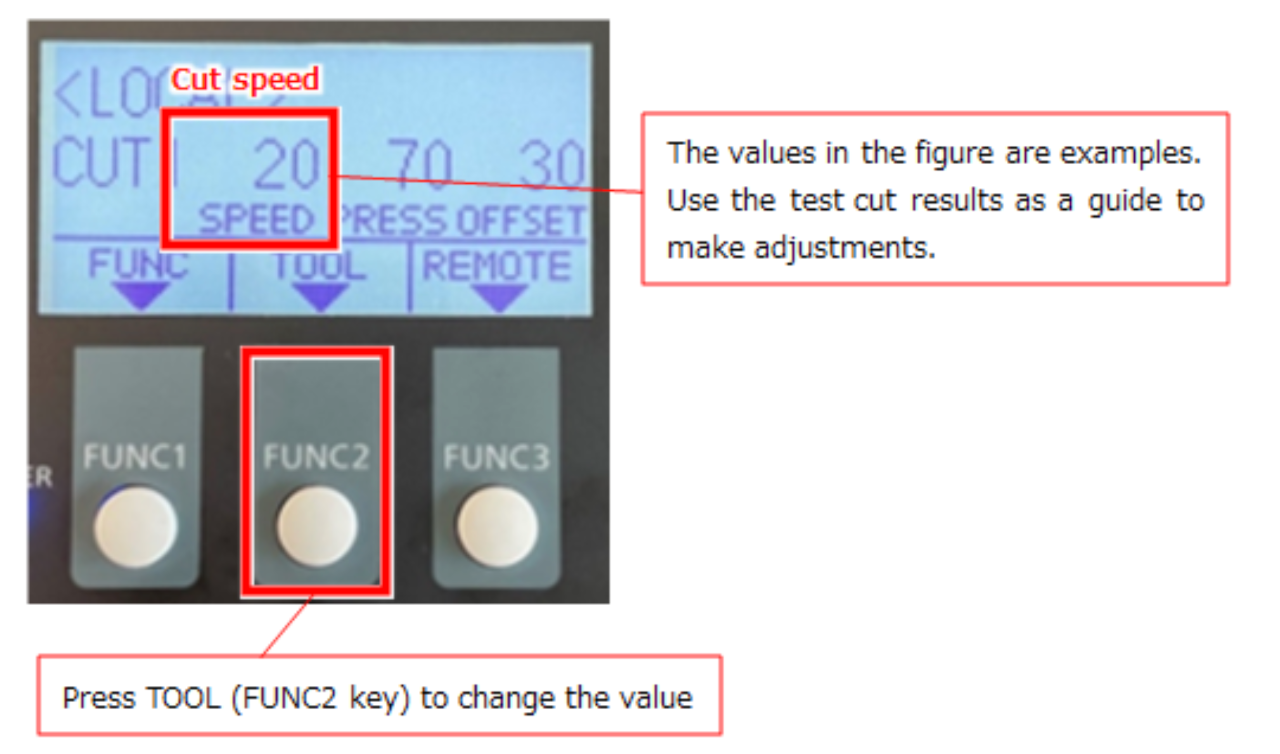

(2) Lower the cutting speed

Lower the cutting speed (SPEED) than the current speed.

When seeking high cutting precision, a speed of 20 cm/s or lower is recommended.

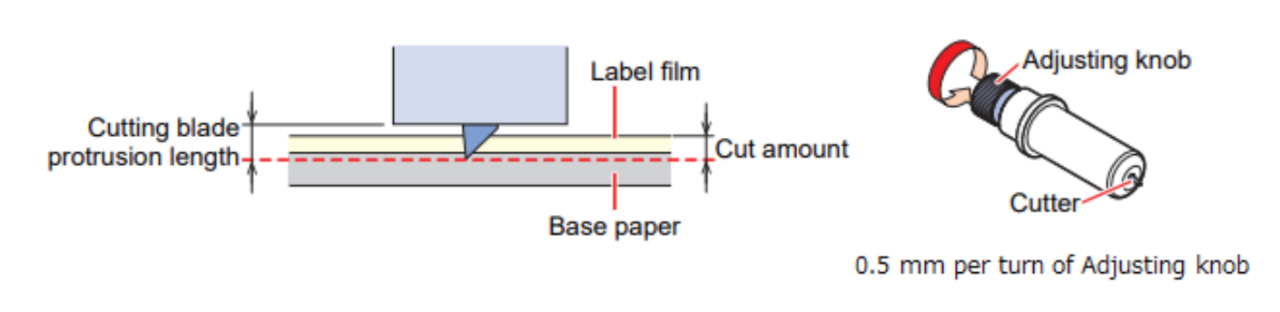

(3) Decrease the [UP SPEED] Decrease the speed at which the cutter and sheet move when the cutter is up. Please refer to the FAQ section "The speed after sheet detection and during cutter up is too fast" for instructions on how to set the [UP SPEED]. Corrective action 3 Adjust the amount of blade extension appropriately - The amount of blade extension should be around = (label film thickness + mounting paper thickness)/2 Reference value: 0.2 to 0.5mm

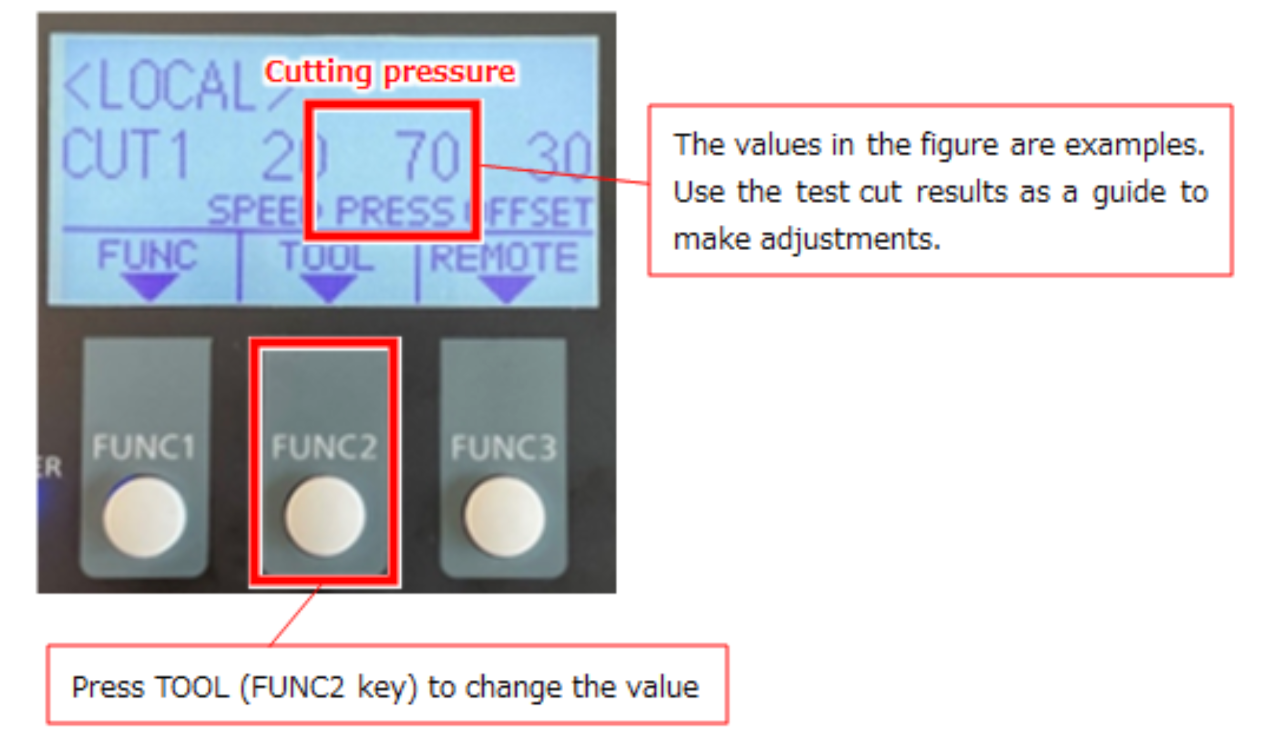

Corrective action 4 Inadequate cut pressure (PRESS) can lead to uncut areas, while excessive pressure may cause over-cutting. If there are uncut areas, increase the pressure, and if there are over-cutting areas, decrease the pressure. The right amount of pressure is when the blade leaves an indentation on the mounting paper after peeling off a test cut.

Recommended cut pressure levels

| PVC sheet | 50 [g] ~ |

| Film type | 30 [g] ~ |

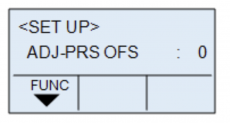

The recommended speed (SPEED), pressure (PRESS), and offset (OFFSET) settings for each type of blade can be found in the video "Mimaki CG Series Introduction of 6 blade types". Corrective action 5 If the [ADJ-PRS OFS] value is too large, the corners may peel off. When cutting corners, the pressure is automatically reduced (by about 5g) to prevent the sheet from peeling. However, if the [ADJ-PRS OFS] is set too high, the pressure during corner cutting may increase and cause peeling. Decrease the [ADJ-PRS OFS] value. Setting range: -9 to 0 to 9

How to display the [ADJ-PRS OFS] menu

(1) Press the FUNC (FUNC1 key) in LOCAL mode.

(2) Press the "∧" and "∨" keys to select [SET UP] and press the [ENTER/HOLD] key.

(3) Press the "∧" and "∨" keys to select [ADJ-PRS OFS] and press the [ENTER/HOLD] key.