- Dispose of the waste ink in the waste ink tank, and perform cleaning of each part and cleaning of the ink draining channel.

Please follow the steps below.

is displayed in SYSTEM ALARM on the touch panel, follow the steps below to replace

with the waste ink tank.

(1) From MENU on the touch panel, tap [MAINTENANCE].

The Maintenance menu is displayed.

(2) Tap [Other maintenance] > [Replace waste ink tank].

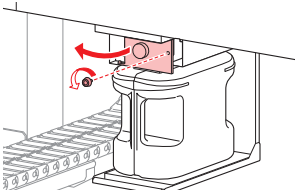

(3) Open the waste ink tank guard.

Remove the screw to open the waste ink tank guard.

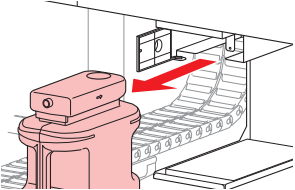

(4) Grasp the handle of the waste ink tank and slide out.

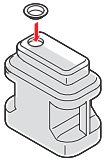

(5) Attach the cap to the removed waste ink tank, and use tape to prevent leakage of waste ink.

* Request an industrial waste disposal company to dispose of waste ink.

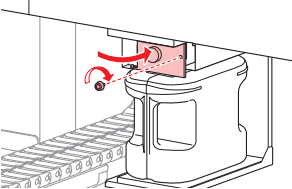

(6) Install a new waste ink tank.

(7) Close the waste ink tank guard.

(8) Tap [Complete] > [Finish] once replacement is complete.

The waste ink level will be reset.

2. Please perform cleaning of the carriage bottom, wiper, cap rubber, etc.

(1) From MENU on the touch panel, tap [MAINTENANCE].

The Maintenance menu is displayed.

(2) Tap [Daily maintenance] > [Head maintenance].

The carriage moves to the maintenance space.

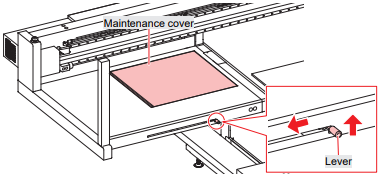

(3) Slide the maintenance cover on the left side of the Y-bar.

Lift the lever and slide it to the left.

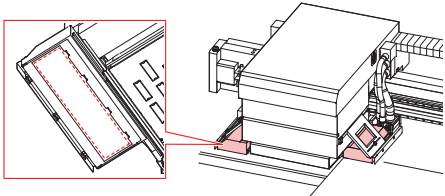

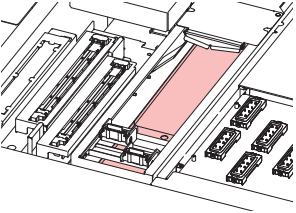

(4) Clean the UV-LED lamp.

Wipe off any ink and dust adhering using a cleaning stick moistened with maintenance liquid.

Wipe off the maintenance liquid. Make sure none remains.

*Do not use excessive force when rubbing the UV-LED lamp with a cleaning stick.

* Do not use excessive force when rubbing the UV-LED lamp with a cleaning stick.

The UV-LED lamp may be damaged.

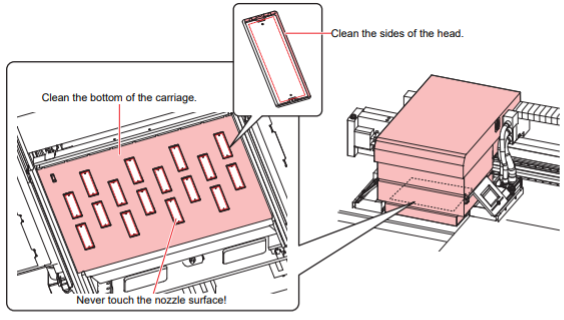

(5) Clean around the print head.

Wipe off any ink and dust adhering using a cleaning stick moistened with maintenance liquid.

Wipe off the maintenance liquid. Make sure none remains.

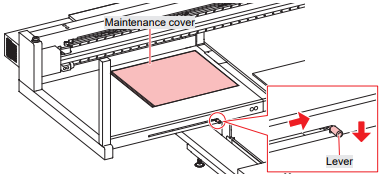

(6) Once cleaning is complete, slide the maintenance cover on the left side of the Y-bar to close it.

* Make sure the maintenance cover is returned to the correct position.

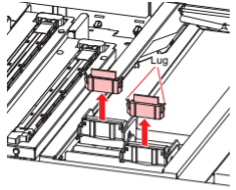

(7) Remove the wiper.

Hold the lugs on both sides of the wiper bracket, then pull out the wiper.

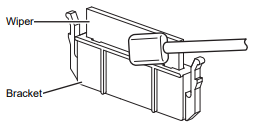

(8) Clean the wiper and bracket.

Wipe off any ink and dust adhering using a cleaning stick moistened with maintenance liquid.

Wipe off the maintenance liquid. Make sure none remains.

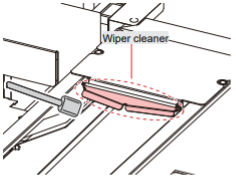

(9) Clean the wiper cleaner.

Wipe off any ink and dust adhering using a cleaning stick moistened with maintenance liquid.

Wipe off the maintenance liquid. Make sure none remains.

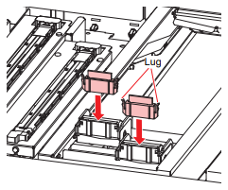

(10) Reattach the wiper at the original position.

(11) Clean the wiper tray.

Wipe off any ink and dust adhering using a cleaning stick moistened with maintenance liquid.

Wipe off the maintenance liquid. Make sure none remains.

Scrape off any dried ink with a spatula or similar tool.

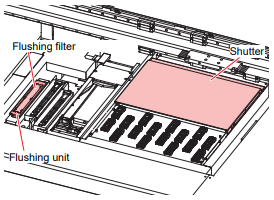

(12) Clean around the flushing filter and on the shutter surface.

Wipe off any ink and dust adhering using a cleaning stick moistened with maintenance liquid.

Wipe off the maintenance liquid. Make sure none remains.

Scrape off any dried ink with a spatula or similar tool.

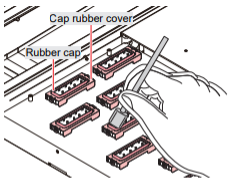

(13) Clean the cap rubber.

Wipe off any ink and dust adhering using a cleaning stick moistened with maintenance liquid.

Wipe off the maintenance liquid. Make sure none remains.

(14) Tap [Complete] > [Finish] once cleaning is complete.

3. Clean the waste ink draining channel.

(1) From MENU on the touch panel, tap [MAINTENANCE].

The Maintenance menu is displayed.

(2) Tap [Weekly maintenance] > [Clean ink discharge path].

The carriage moves over the table. The suction pump will start operating.

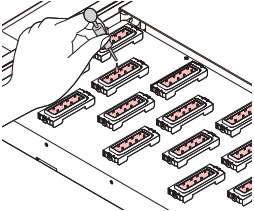

(3) Apply maintenance liquid to the caps.

Use a syringe to draw up and apply maintenance liquid to the caps.

(4) Tap [Complete].

Maintenance liquid is discharged from the pump tube (waste ink draining channel below the cap).

The carriage returns to the station.

* If the "0604 WASTE INK TANK NEAR FULL" or "0666 WASTE INK TANK FULL" error appears

after maintenance, please follow step 1. to replace it with a new waste ink tank.

[Important]

Please check the following to prevent ink path clogging and to protect the nozzles.

(1) Please keep the main power switch on during long-term storage.

The nozzle clogging prevention function works automatically to protect the printhead nozzles.

Leaving the main power turned off for a long period of time may cause the nozzles to be clogged.

(2) Check the ink remaining level.

The Maintenance solution suction works during cleaning operation of ink discharge path.

During ink suction, nozzle wash does not start if "INK END" or "INK NEAR END" is detected.

We recommend setting an ink bottle with sufficient remaining amount,

as ink is consumed during regular maintenance while the printer is not in use.

Please also refer to these videos for reference.